Forklifts are essential tools in many industries, but they can also be incredibly dangerous if not operated and maintained correctly. Accidents involving forklifts can result in serious injuries and even fatalities. This article will outline key safety precautions for forklift operators, pedestrians, and supervisors to minimize risks and create a safer working environment.

1. Operator Training and Certification

Formal Training: All forklift operators must undergo comprehensive training programs that cover:

Vehicle operation: Safe starting, stopping, steering, lifting, lowering, and traveling.

Load stability: Center of gravity, load balancing, and proper load handling techniques.

Workplace hazards: Identifying and mitigating potential dangers, such as uneven surfaces, obstructions, and blind spots.

Traffic safety: Rules of the road within the facility, pedestrian awareness, and right-of-way protocols.

Pre-operational inspections: Daily checks of tires, brakes, lights, horns, and other critical components.

Emergency procedures: Responding to equipment malfunctions, spills, and accidents.

Certification: Upon successful completion of training, operators should be certified and re-certified at regular intervals (typically annually) to ensure ongoing competency.

2. Pre-Operational Inspections

Daily Checks: Before each shift, operators must conduct a thorough pre-operational

inspection of the forklift, including:

Tires: Check for proper inflation and wear and tear.

Brakes: Test for proper function and responsiveness.

Steering: Ensure smooth and accurate steering.

Lights and Horn: Verify functionality for optimal visibility and communication.

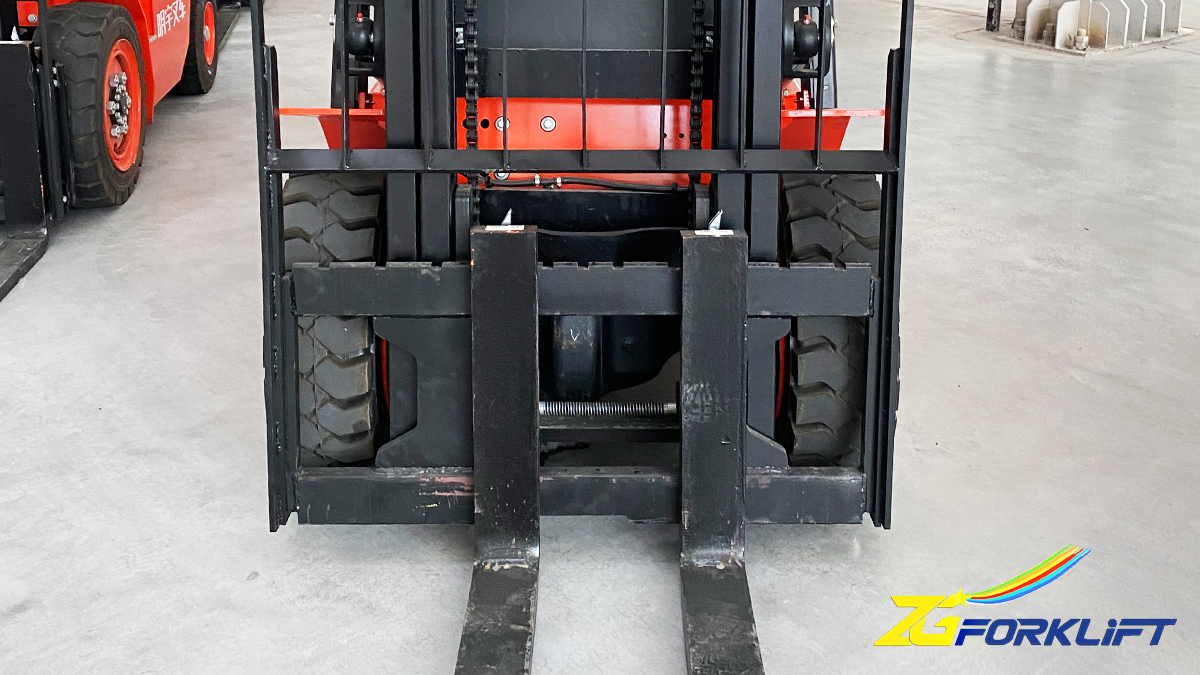

Mast and Forks: Inspect for any damage, cracks, or signs of wear.

Hydraulics: Check for leaks and proper fluid levels.

Battery (for electric forklifts): Ensure adequate charge and no signs of damage.

Reporting Defects: Any identified defects must be immediately reported to maintenance personnel for repair. Operate the forklift only if it is in safe working condition.

3. Safe Operating Practices

Load Capacity: Never exceed the rated load capacity of the forklift. Ensure the load is properly balanced and secured to prevent tipping or falling.

Travel Speed: Maintain a safe and appropriate speed, especially when carrying loads or navigating corners. Avoid sudden stops or starts.

Load Handling:

Lifting: Raise the load smoothly and slowly. Avoid jerking or sudden movements.

Lowering: Lower the load gradually and controlled.

Turning: Reduce speed and ensure the load is stable before turning corners.

Tilting: Only tilt the mast forward when necessary and within safe limits.

Pedestrian Awareness: Always be aware of pedestrians in the vicinity. Sound the horn when necessary to alert others. Yield to pedestrians whenever possible.

Clear Aisles: Maintain clear and unobstructed aisles for safe forklift traffic flow.

Obstructions: Be mindful of overhead obstructions, such as pipes, beams, and sprinkler systems.

Ramps and Slopes: Exercise extreme caution when operating on ramps and slopes. Maintain a slow and steady speed.

Passenger Restrictions: Never allow passengers on the forklift unless specifically designed for two operators.

4. Pedestrian Safety

Designated Walkways: Establish and clearly mark designated pedestrian walkways to separate pedestrian and forklift traffic.

Visibility: Wear high-visibility clothing to enhance visibility to forklift operators.

Awareness: Be aware of your surroundings and the potential presence of forklifts.

Communication: Communicate with forklift operators using eye contact, hand signals, or verbal warnings.

Avoid Blind Spots: Never walk or stand in the blind spots of a forklift, especially behind or to the sides.

Never Walk Under a Raised Load: This is a critical safety rule that must be strictly enforced.

5. Forklift Maintenance

Regular Maintenance: Schedule regular maintenance checks and repairs by qualified technicians.

Battery Maintenance (for electric forklifts): Follow proper charging procedures and ensure battery maintenance is performed according to manufacturer recommendations.

Tire Maintenance: Regularly inspect and maintain tire pressure for optimal performance and safety.

6. Workplace Safety Measures

Traffic Flow: Implement clear traffic flow patterns and signage to guide forklift and pedestrian movement.

Speed Limits: Establish and enforce appropriate speed limits within the facility.

Spotters: Utilize spotters in areas with limited visibility to assist operators and warn pedestrians.

Forklift Parking: Designate safe and clearly marked parking areas for forklifts when not in use.

Emergency Response: Develop and implement emergency procedures for accidents, spills, and other unforeseen events.

7. Environmental Considerations

Emissions Control: Ensure forklifts comply with all applicable emissions regulations.

Battery Charging: Implement proper battery charging procedures to minimize environmental impact.

Fuel Storage: Properly store and handle fuel to prevent spills and environmental contamination.

8. Continuous Improvement

Safety Audits: Conduct regular safety audits to identify and address potential hazards.

Incident Investigations: Thoroughly investigate all forklift accidents to determine root causes and implement corrective actions.

Safety Training: Continuously reinforce safety training through regular refresher courses and toolbox talks.

Employee Feedback: Encourage employee feedback on safety concerns and implement suggestions for improvement.

Post time:Dec.24.2024