Introduction

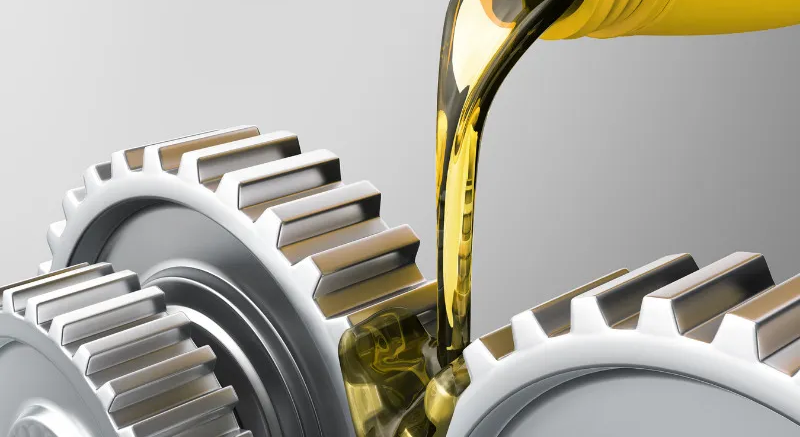

Wheel loaders are indispensable machines in various industries, from construction and mining to agriculture and material handling. To ensure optimal performance and longevity, proper lubrication is crucial. This article delves into the types of oils and lubricants commonly used in wheel loaders, their specific functions, and best practices for maintenance and replacement.

Understanding the Lubrication Needs of Wheel Loaders

Wheel loaders have a complex system of components that require different types of lubricants. The primary lubrication points include:

- Engine: The heart of the machine, requiring engine oil to reduce friction, dissipate heat, and protect against wear.

- Hydraulic System: This system powers various functions like lifting, tilting, and steering, relying on hydraulic oil for smooth operation and efficient energy transfer.

- Transmission: The transmission, whether manual or automatic, needs transmission fluid to ensure smooth gear shifting and protect internal components.

- Axles: The front and rear axles require axle oil to lubricate the gears and bearings, reducing friction and wear.

- Steering System: The steering system, often hydraulically powered, needs hydraulic oil to function properly.

- Working Devices: The bucket, boom, and other working devices have numerous moving parts, including pins and bushings, that require lubrication with grease.

Types of Lubricants Used in Wheel Loaders

-

Engine Oil:

- Function: Lubricates engine components, reduces friction, dissipates heat, and protects against wear and corrosion.

-

Types:

- Mineral Oil: A traditional option, suitable for older engines.

- Synthetic Oil: Offers superior performance, especially in extreme conditions, with better resistance to heat, cold, and oxidation.

- High-Performance Engine Oil: Formulated for high-performance engines, providing excellent protection and fuel economy.

-

Hydraulic Oil:

- Function: Transmits power in the hydraulic system, lubricates components, and prevents corrosion.

- Types:

- Petroleum-Based Hydraulic Oil: A common choice, offering good performance at moderate temperatures.

- Synthetic Hydraulic Oil: Provides excellent performance in extreme conditions, with better resistance to heat, cold, and oxidation.

- Biodegradable Hydraulic Oil: Environmentally friendly option, suitable for applications where spills may occur.

-

Transmission Fluid:

- Function: Lubricates transmission components, reduces friction, and ensures smooth gear shifting.

-

Types:

- Manual Transmission Fluid: Specifically designed for manual transmissions, providing adequate lubrication and protection.

- Automatic Transmission Fluid: Formulated for automatic transmissions, ensuring smooth shifting and efficient power transfer.

-

Axle Oil:

- Function: Lubricates the gears and bearings in the axles, reducing friction and wear.

-

Types:

- Gear Oil: A common choice, offering good performance and protection.

- Synthetic Axle Oil: Provides superior performance, especially in extreme conditions, with better resistance to heat, cold, and oxidation.

-

Grease:

- Function: Lubricates various components, including pins, bushings, and bearings, reducing friction and wear.

-

Types:

- Lithium-Based Grease: A versatile grease suitable for most applications.

- Calcium-Based Grease: Offers good water resistance and is suitable for applications exposed to moisture.

- Synthetic Grease: Provides excellent performance in extreme conditions, with better resistance to heat, cold, and oxidation.

Lubrication Schedule and Best Practices

A well-defined lubrication schedule is essential to maintain the optimal performance of a wheel loader. Here are some general guidelines:

- Engine Oil: Change the engine oil and filter at recommended intervals, typically every 250-500 hours of operation.

- Hydraulic Oil: Monitor the hydraulic oil level and quality regularly. Replace the oil and filter as needed, following the manufacturer's recommendations.

- Transmission Fluid: Change the transmission fluid and filter at recommended intervals, typically every 500-1000 hours of operation.

- Axle Oil: Change the axle oil and filter at recommended intervals, typically every 1000-2000 hours of operation.

- Grease: Grease fittings should be lubricated regularly, typically every 50-100 hours of operation.

Additional Tips:

- Use high-quality lubricants: Always use lubricants that meet or exceed the manufacturer's specifications.

- Follow the manufacturer's recommendations: Refer to the owner's manual for specific lubrication intervals and procedures.

- Keep the machine clean: Regularly clean the machine to remove dirt and debris that can contaminate lubricants.

- Monitor oil levels and quality: Check oil levels regularly and monitor the oil's condition for signs

Post time:Mar.08.2021