Forklift vs. Excavator: A Comparative Analysis

Both forklifts and excavators are essential pieces of heavy equipment found in various industries, but they serve distinct purposes and possess unique characteristics. This article will delve into the key differences between these two machines, exploring their design, functionality, and applications to provide a comprehensive understanding of their respective roles.

Design and Construction

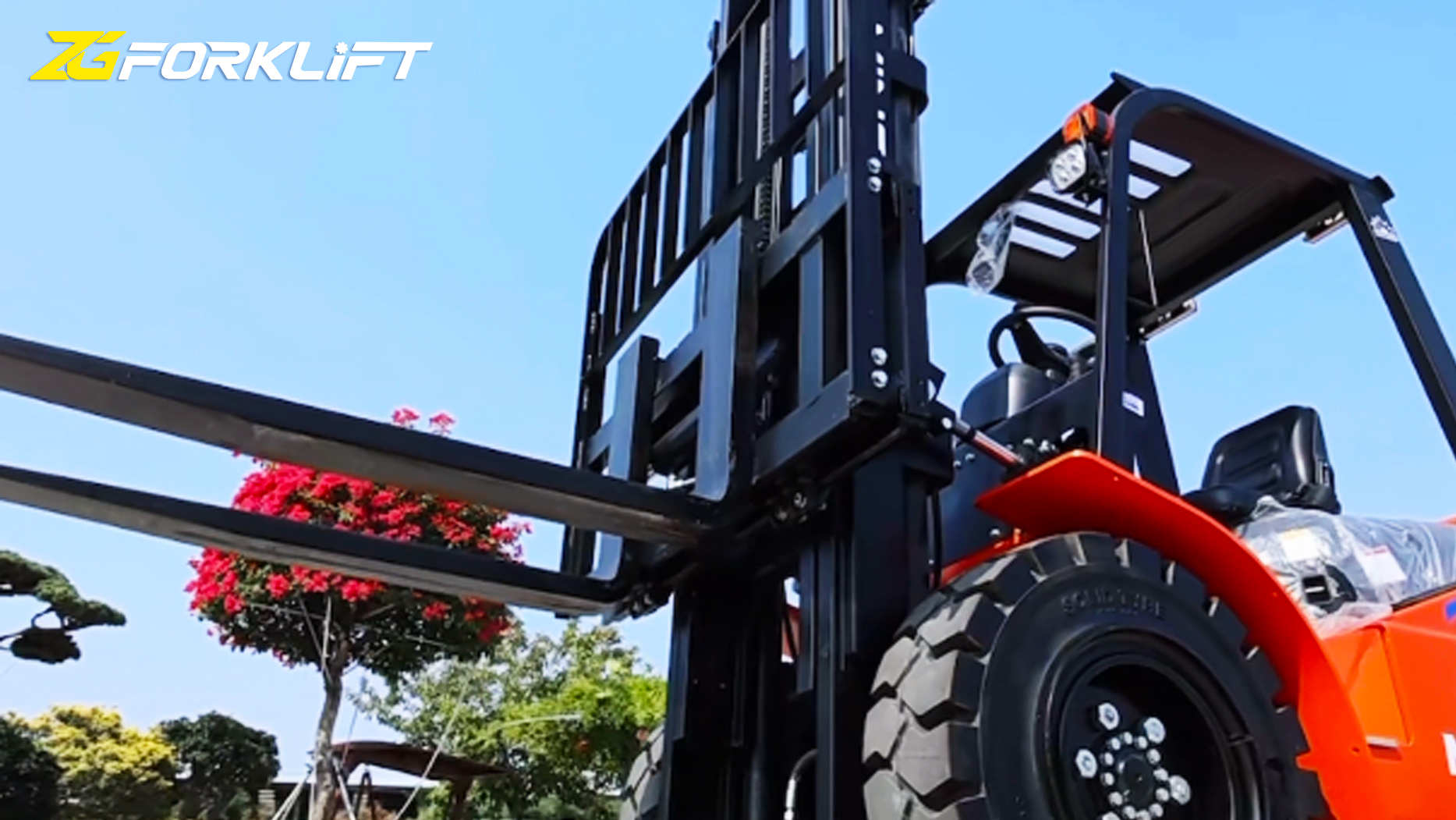

Forklift:

Primary Function: Primarily designed for lifting and transporting materials horizontally.

Key Components:

Chassis: Typically a compact frame with either pneumatic or cushion tires.

Mast: A vertical column that supports the lifting forks.

Forks: Two prongs that penetrate and engage with pallets or other loads.

Counterweight: A heavy weight positioned at the rear to counterbalance the lifted load and prevent tipping.

Hydraulic System: Powers the lifting and lowering of the forks.

Variations: Forklifts come in various types, including electric, diesel, and propane-powered models, each with specific advantages and limitations.

Excavator:

Primary Function: Primarily designed for digging, excavating, and moving earth.

Key Components:

Chassis: Often equipped with tracks or wheels for mobility.

Cab: An enclosed compartment for the operator.

Boom: A long, articulated arm that swings horizontally.

Stick: A shorter arm attached to the boom, providing additional reach and digging force.

Bucket: A scoop attached to the stick for digging, scooping, and loading materials.

Hydraulic System: Powers the movement of the boom, stick, and bucket.

Variations: Excavators come in various sizes and configurations, including crawler excavators (tracked), wheeled excavators, and mini excavators.

Functionality and Capabilities

Forklift:

Lifting and Transporting:

Loading and unloading trucks.

Moving materials within warehouses, factories, and construction sites.

Stacking and retrieving materials in storage areas.

Handling palletized goods efficiently.

Versatility:

Can be equipped with various attachments, such as side-shifters, rotators, and clamps, to enhance their capabilities.

Excavator:

Digging and Excavating:

Creating trenches for utilities.

Digging foundations for buildings.

Excavating materials during construction and demolition projects.

Clearing land and preparing sites for development.

Material Handling:

Loading and unloading trucks with loose materials like dirt, gravel, and sand.

Moving and placing heavy objects.

Demolition work, such as breaking concrete and removing debris.

Maneuverability and Operating Environment

Forklift:

Highly Maneuverable:

Designed for operation in confined spaces.

Tight turning radius allows for easy navigation in narrow aisles and tight corners.

Suitable for indoor and outdoor use, depending on the tire type.

Excavator:

Less Maneuverable:

Generally larger and less agile than forklifts.

May have difficulty navigating tight spaces and confined areas.

More suited for open areas and construction sites.

Safety Considerations

Forklift:

Operator Training: Essential for safe operation, including load stability, proper lifting techniques, and awareness of surroundings.

Load Capacity: Exceeding load capacity can lead to tipping and serious accidents.

Traffic Management: Implementing traffic control measures to prevent collisions with pedestrians and other vehicles.

Excavator:

Operator Training: Crucial to ensure safe operation and prevent accidents.

Ground Stability: Operating on unstable ground can increase the risk of tipping.

Overhead Hazards: Be aware of overhead power lines and other obstacles.

Excavation Safety: Proper shoring and bracing are essential to prevent cave-ins during excavation work.

Applications

Forklift:

Warehousing and Logistics: Loading and unloading trucks, moving goods within warehouses, and managing inventory.

Manufacturing: Material handling, assembly line operations, and transporting finished products.

Construction: Loading and unloading building materials, transporting equipment, and assisting with construction tasks.

Agriculture: Moving feed, hay bales, and other agricultural products.

Excavator:

Construction: Excavation, trenching, demolition, and site preparation.

Landscaping: Creating ponds, digging drainage ditches, and shaping terrain.

Mining and Quarrying: Excavating and loading materials.

Utility Work: Installing and repairing underground utilities, such as water and sewer lines.

Cost and Maintenance

Forklift:

Generally more affordable than excavators, especially smaller models.

Maintenance costs vary depending on the type and usage.

Battery replacement is a significant cost for electric forklifts.

Excavator:

Significantly more expensive than forklifts, especially larger models.

Higher maintenance costs due to the complexity of the hydraulic system and other components.

Regular maintenance is crucial to ensure optimal performance and prevent costly repairs.

Conclusion

Forklifts and excavators are both vital pieces of heavy equipment, but they serve distinct purposes and possess unique characteristics.

Description:Forklift vs. Excavator: A comparative analysis of their design, functionality, and applications. Discover the key differences, including lifting capacity, digging power, maneuverability, and safety considerations for these essential construction and material handling machines.

Post time:Jan.15.2025