A pallet truck, also known as a pallet jack, hand pallet truck, pump truck, or jigger, is a manually operated device used to lift and transport palletized loads. It's a cornerstone of material handling in warehouses, distribution centers, retail stores, and various other industries.

Key Components of a Pallet Truck:

Forks: These extend horizontally and are designed to slide under the pallet.

Hydraulic Pump: This is the core mechanism. By pumping the handle, hydraulic fluid is pressurized, lifting the forks and the loaded pallet.

Handle: This is used to operate the hydraulic pump, steer the truck, and control movement.

Wheels: Typically, two large rear wheels and two smaller front wheels provide stability and maneuverability.

Frame: The sturdy frame provides structural support for all the components.Types of Pallet Trucks:

Standard Pallet Truck:

The most common type.

Simple and easy to operate.

Ideal for short-distance transport and moderate loads.

High-Lift Pallet Truck:

Can lift pallets to higher heights.

Useful for loading and unloading trucks or reaching higher shelves.

Low-Profile Pallet Truck:

Designed for use in areas with limited clearance.

Ideal for working under low-hanging structures or in confined spaces.

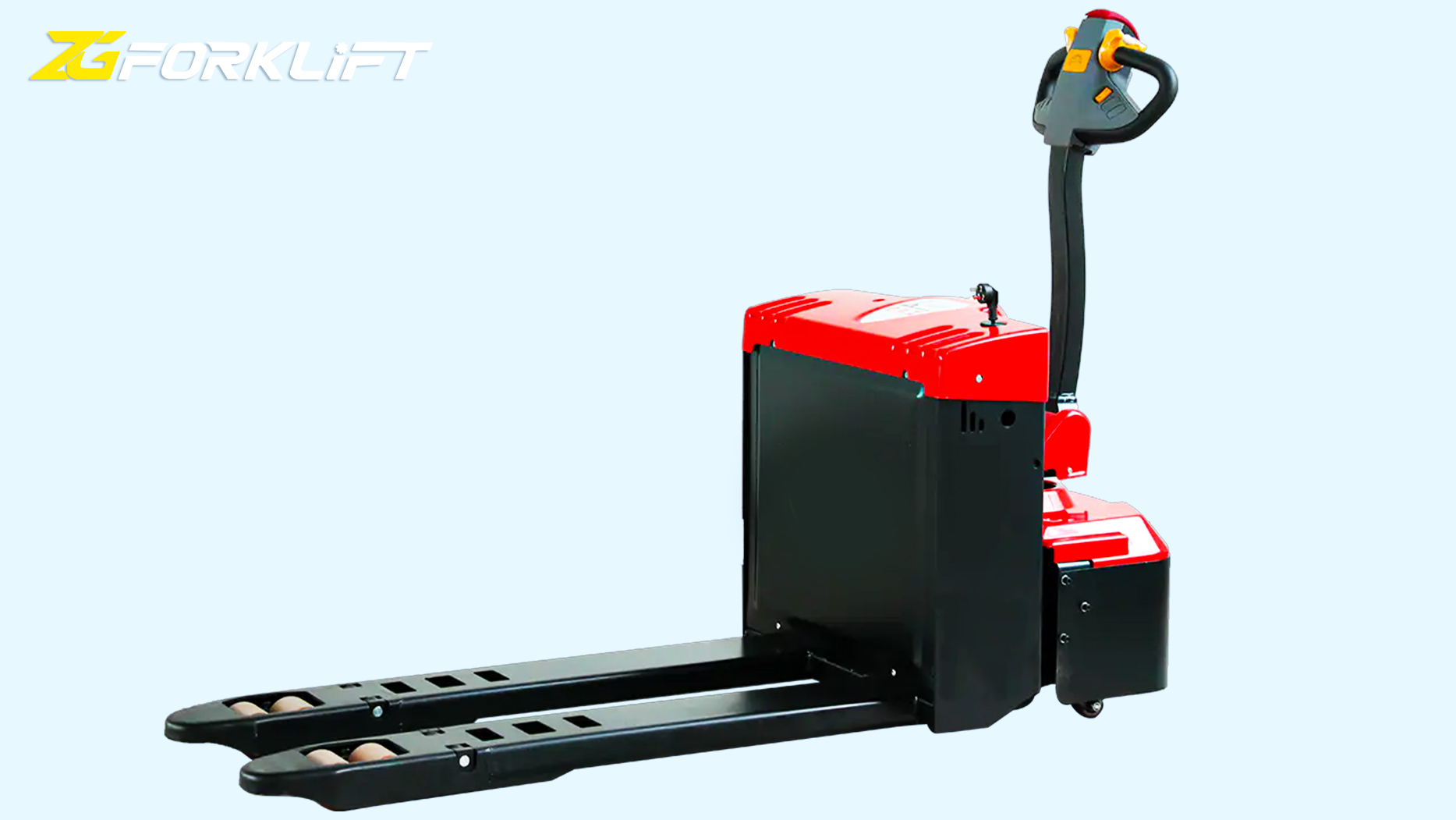

Electric Pallet Truck:

Powered by a battery.

Offers greater ease of use, especially for heavy loads or long distances.

Can be further categorized into:

Walkie Pallet Trucks: The operator walks alongside the truck.

Rider Pallet Trucks: The operator stands on a platform while operating the truck.Specialized Pallet Trucks:

Stainless Steel Pallet Trucks: Used in cleanroom environments or where hygiene is critical.

Rough Terrain Pallet Trucks: Designed for use on uneven surfaces or outdoors.

Weighing Pallet Trucks: Integrated with scales for accurate weight measurement.

Operating a Pallet Truck:

Approach the Pallet: Position the forks squarely under the pallet.

Engage the Pump: Pump the handle repeatedly to lift the pallet.

Steer and Maneuver: Use the handle to guide the truck in the desired direction.

Lower the Pallet: Release the pressure on the pump handle to lower the pallet.

Safety Considerations:

Load Capacity: Never exceed the rated load capacity of the pallet truck.

Proper Lifting Techniques: Avoid lifting heavy loads manually. Use the pallet truck to lift and transport all loads.

Footwear: Wear appropriate footwear with good grip to maintain balance and prevent injuries.

Clear Pathways: Ensure clear and unobstructed pathways for safe movement.

Regular Maintenance: Perform regular maintenance checks, such as checking tire pressure, inspecting the hydraulic system, and lubricating moving parts.

Operator Training: Provide proper training to all operators on safe operating procedures.

Benefits of Using Pallet Trucks:Increased Efficiency: Significantly improves the speed and efficiency of material handling operations.

Reduced Manual Labor: Minimizes the need for manual lifting, reducing the risk of injuries.

Improved Productivity: Enables faster and more efficient movement of goods within the warehouse or production facility.

Cost-Effectiveness: Reduces labor costs and improves overall operational efficiency.

Versatility: Suitable for a wide range of applications and industries.

Choosing the Right Pallet Truck:

Load Capacity: Determine the weight of the heaviest loads that will be handled.

Operating Environment: Consider the type of environment where the pallet truck will be used (warehouse, outdoor, etc.).

Maneuverability: Assess the space available for maneuvering the truck.

Budget: Determine the available budget and choose a model that fits within your constraints.

Operator Requirements: Consider the physical demands of operating the truck and choose a model that is comfortable and easy to use for operators.

Conclusion

Pallet trucks are essential tools in modern material handling operations. By understanding the different types of pallet trucks available and following safe operating practices, businesses can significantly improve efficiency, reduce costs, and enhance workplace safety.

Post time:Jan.11.2025