The excavator, a ubiquitous sight on construction sites and in various industrial settings, is a powerful and versatile machine capable of performing a wide array of tasks. While its primary function is often associated with digging, the excavator's capabilities extend far beyond simple excavation. This article delves into the technical aspects of excavators, exploring their design, functionality, diverse applications, and the technologies that drive their performance.

I. The Anatomy of an Excavator:

Understanding the functions of an excavator requires familiarity with its key components:

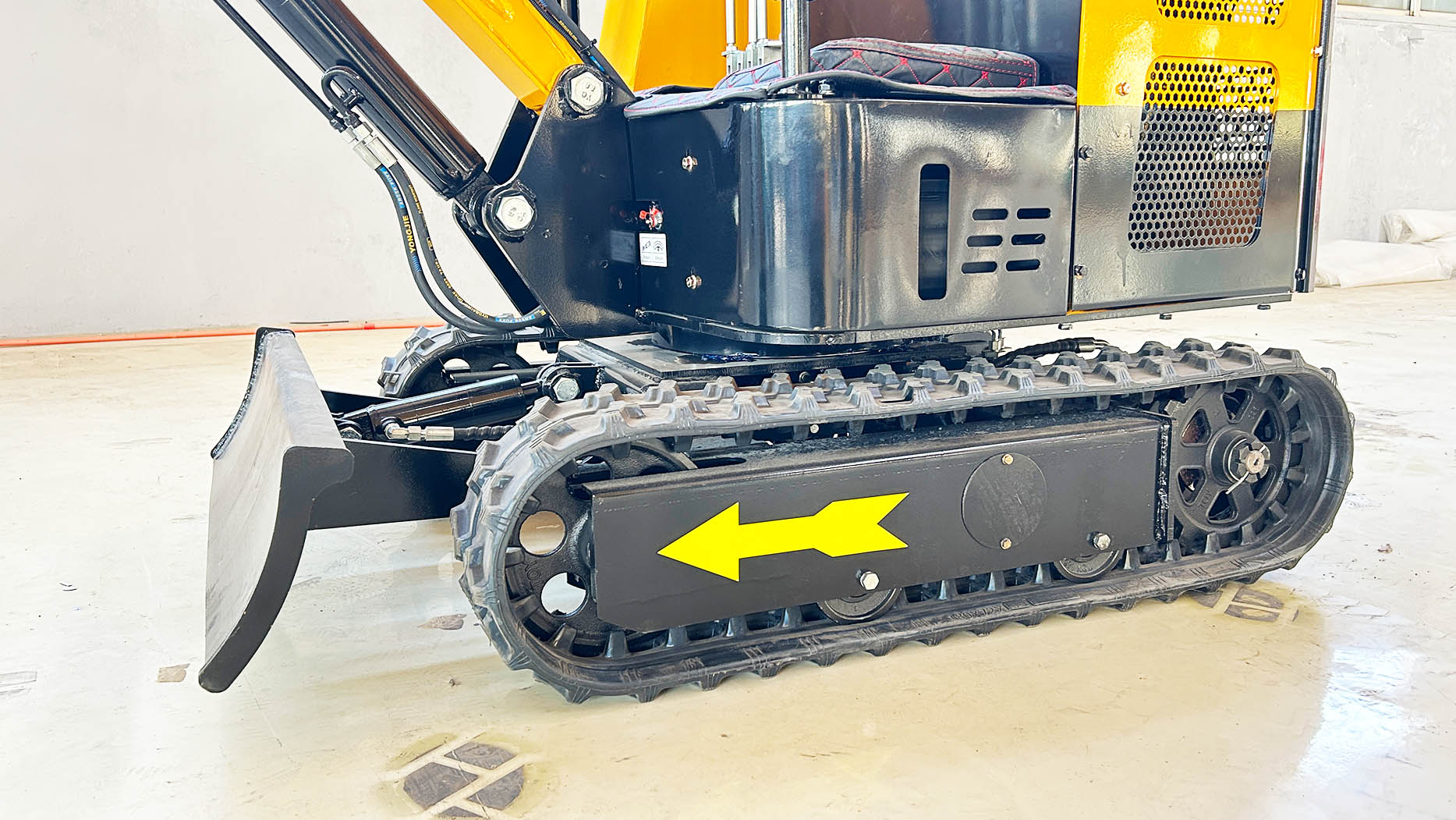

Undercarriage:

This consists of tracks or wheels that provide mobility and stability. Tracks are preferred for rough terrain and soft ground, offering superior traction and weight distribution. Wheeled excavators are better suited for paved surfaces and faster travel.

The undercarriage includes a drive system, typically powered by hydraulic motors, enabling the excavator to move forward, backward, and turn.

Turret (Superstructure):

The turret is the rotating upper structure that houses the engine, operator cab, and hydraulic components.

A slew ring allows the turret to rotate 360 degrees, providing flexibility and efficiency in positioning the boom and arm.

Boom:

The boom is the primary lifting arm, connected to the turret. It provides the vertical reach and lifting capacity of the excavator.

Boom designs vary depending on the excavator's size and intended application.

Arm (Stick):

The arm is connected to the end of the boom and provides the horizontal reach and digging force.

The arm's length and design influence the excavator's digging depth and reach.

Bucket:

The bucket is the primary digging attachment, available in various sizes and shapes to suit different tasks.

Other attachments can be easily interchanged with the bucket, expanding the excavator's versatility.

Hydraulic System:

The hydraulic system is the heart of the excavator, powering all its movements.

Hydraulic pumps, valves, and cylinders control the flow of hydraulic fluid, enabling precise and powerful operation.

Engine:

The engine, typically a diesel engine, provides the power for the hydraulic system and the drive system.

Modern engines are designed to meet stringent emissions standards while delivering high performance.

Operator Cab:

The operator cab provides a comfortable and ergonomic workspace for the operator.

It includes controls for all excavator functions, as well as monitoring systems and safety features.

II. Core Functions and Applications:

Excavators perform a wide range of functions, making them indispensable in various industries:

Excavation:

This is the excavator's primary function, involving digging trenches, foundations, and other excavations.

Excavators can handle various soil types, from loose earth to hard rock.

Trenching:

Excavators are used to dig trenches for pipelines, cables, and other utilities.

Precise control of the boom and arm allows for accurate trenching.

Material Handling:

Excavators can be used to move and load materials, such as soil, gravel, and debris.

Attachments, such as grapples and magnets, enhance material handling capabilities.

Demolition:

Excavators are used in demolition projects to tear down structures and clear debris.

Attachments, such as hydraulic breakers and shears, are used to break concrete and steel.

Grading and Leveling:

Excavators can be used to grade and level surfaces for construction and landscaping.

Precise control of the bucket allows for accurate grading.

Dredging:

Excavators are used in dredging operations to remove sediment from waterways.

Long-reach excavators are used for dredging in deep water.

Mining:

Excavators are used in mining operations to extract ore and other minerals.

Large excavators are used in open-pit mining.

Forestry:

Excavators equipped with forestry attachments are used for tasks like felling trees, moving logs, and site preparation.

Landscaping:

Excavators are used to move earth, create ponds, and shape landscapes.

III. Technological Advancements:

Modern excavators incorporate advanced technologies that enhance their performance, efficiency, and safety:

Hydraulic Systems:

Advanced hydraulic systems with electronic controls provide precise and responsive operation.

Load-sensing hydraulics optimize power distribution, improving fuel efficiency.

Engine Technology:

Modern engines meet stringent emissions standards while delivering high power and fuel efficiency.

Electronic engine management systems optimize performance and reduce fuel consumption.

GPS and Telematics:

GPS and telematics systems provide real-time data on excavator location, performance, and maintenance needs.

These systems can be used for remote monitoring and diagnostics.

Grade Control Systems:

Grade control systems use GPS and laser technology to automate grading and leveling tasks.

These systems improve accuracy and efficiency, reducing the need for manual labor.

Machine Control Systems:

Machine control systems help the operator to maintain desired digging depths, slopes, and other design parameters.

Safety Features:

Modern excavators are equipped with advanced safety features, such as rollover protection systems (ROPS), falling object protection systems (FOPS), and backup cameras.

Proximity sensors and collision avoidance systems are becoming more common.

Hybrid and Electric Excavators:

To reduce emissions and noise, hybrid and fully electric excavators are being developed and implemented.

These machines offer environmental benefits and reduced operating costs.

IV. Attachment Versatility:

The versatility of excavators is greatly enhanced by the wide range of available attachments:

Hydraulic Breakers: Used for breaking concrete and rock.

Hydraulic Shears: Used for cutting steel and other materials.

Grapples: Used for handling logs, debris, and other materials.

Augers: Used for drilling holes.

Compactors: Used for compacting soil and asphalt.

Rippers: Used for loosening hard ground and rock.

Tilting Buckets: Used for precise grading and shaping.

Mulchers: Used for clearing vegetation.

Magnets: Used for lifting metal debris.

V. Maintenance and Operation:

Proper maintenance and operation are essential to ensure the longevity and performance of excavators:

Regular Inspections: Conduct daily pre-operation checks and regular maintenance inspections.

Lubrication: Grease all lubrication points regularly.

Fluid Changes: Change engine oil, hydraulic fluid, and other fluids at the recommended intervals.

Filter Replacement: Replace air filters, fuel filters, and hydraulic filters regularly.

Operator Training: Ensure that operators are properly trained and certified.

Safety Procedures: Follow all safety procedures and guidelines.

In conclusion, the excavator is a powerful and versatile machine that plays a crucial role in various industries. Its ability to perform a wide range of tasks, combined with technological advancements, makes it an indispensable tool for construction, mining, and other demanding applications.

Post time:Feb.21.2025