I. Introduction

"In the bustling heart of warehouses, construction sites, and manufacturing plants, diesel forklifts are indispensable workhorses. Their robust power and reliability make them essential for moving heavy loads and maintaining operational efficiency. However, like any complex machinery, diesel forklifts require consistent and meticulous maintenance to prevent costly breakdowns and ensure optimal performance. This article aims to shed light on the common maintenance issues that plague diesel forklifts and, more importantly, provide practical strategies to prevent them. By understanding these challenges and implementing proactive maintenance practices, businesses can significantly reduce downtime, extend the lifespan of their equipment, and enhance workplace safety. We will explore engine, hydraulic, electrical, undercarriage, and operator-related issues, culminating in a guide to effective preventative maintenance."

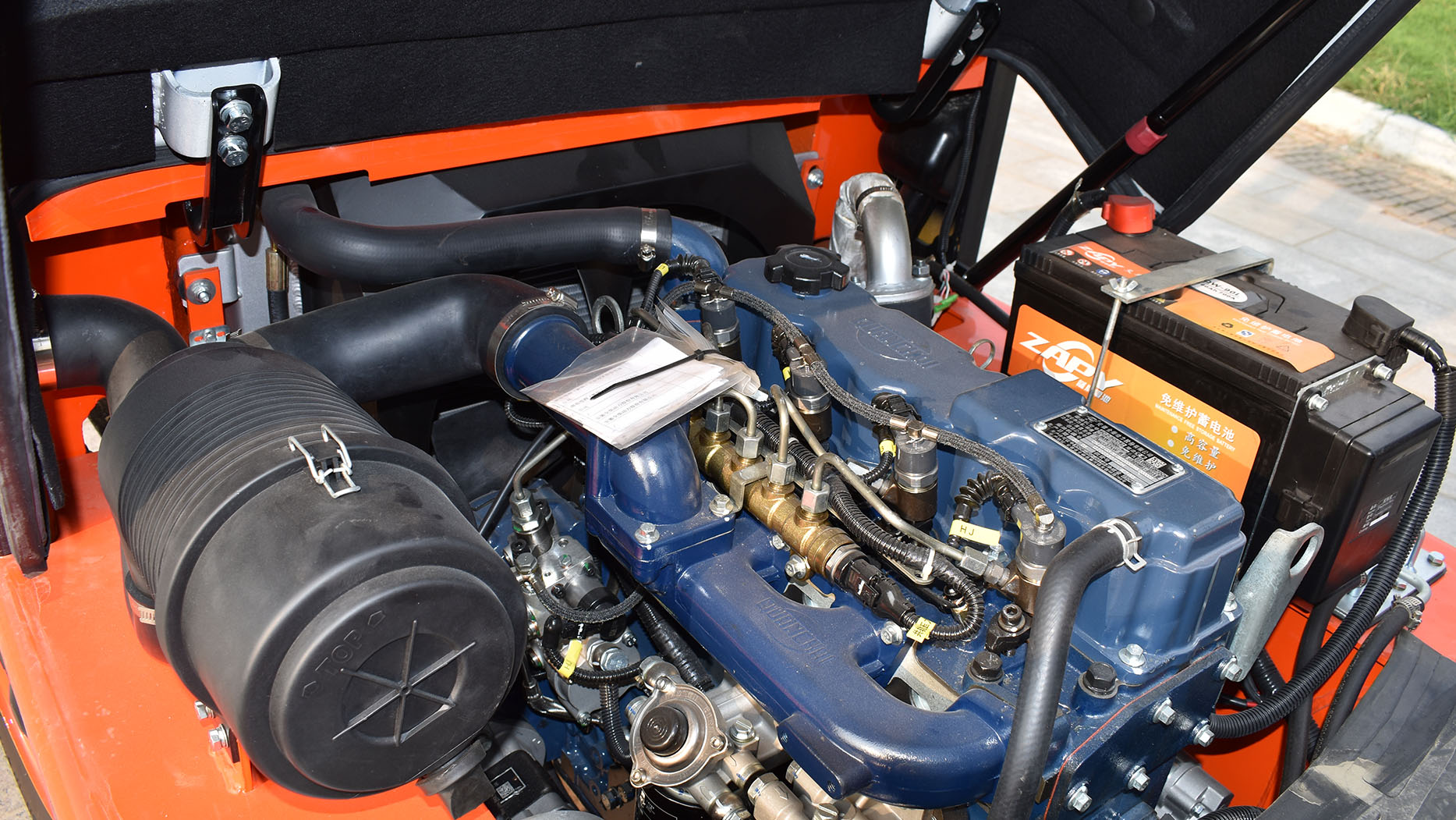

II. Engine Maintenance Challenges

A. Fuel System Issues:

"Diesel fuel is susceptible to contamination, particularly water and particulates. Contaminated fuel can clog filters, damage injectors, and lead to engine malfunctions. Regular fuel filter replacements and the use of high-quality fuel are essential. Water separators should be used to prevent water from entering the fuel system. Injector problems can arise from poor fuel quality, requiring professional cleaning or replacement."

B. Oil and Lubrication:

"Regular oil changes are crucial for engine longevity. Using the correct oil type and viscosity, as specified by the manufacturer, is vital. Proper lubrication of all moving engine parts reduces friction and wear. Regularly check oil levels and inspect for leaks."

C. Cooling System Problems:

"Overheating is a common issue caused by coolant leaks, blockages, or a faulty thermostat. Regularly check coolant levels and inspect hoses, radiators, and belts for wear and tear. Ensure the cooling system is free from debris and that the coolant mixture is correct."

D. Air Intake System:

"Clogged air filters restrict airflow, reducing engine efficiency and increasing fuel consumption. Regular air filter cleaning or replacement is necessary. Inspect the intake manifold for leaks or damage."

E. Exhaust System:

"Exhaust leaks can lead to dangerous fumes and reduced engine performance. Regularly inspect the exhaust system for leaks and damage. Diesel particulate filters (DPF) require periodic regeneration or cleaning to prevent clogging."

III. Hydraulic System Maintenance

A. Hydraulic Fluid:

"Hydraulic fluid contamination and degradation can lead to system failures. Regular fluid checks and changes are crucial. Ensure the fluid is clean and free from contaminants. Fluid analysis can help determine the health of the hydraulic fluid."

B. Hoses and Fittings:

"Hydraulic hoses and fittings are subject to high pressure and wear. Inspect them regularly for leaks, cracks, and damage. Proper hose routing and secure fittings prevent premature failure."

C. Cylinders and Seals:

"Seal leaks and cylinder damage can lead to fluid loss and reduced system performance. Regular inspections and maintenance are essential. Replace worn or damaged seals promptly."

D. Hydraulic pumps and valves.

"Wear and tear on pumps and valves can cause pressure loss, and system ineffectiveness. Testing the system pressures, and regular maintenance is required."

IV. Electrical System Issues

A. Battery Maintenance:

"Battery terminal corrosion and loose connections can lead to starting problems. Regularly clean terminals and ensure connections are tight. Check battery electrolyte levels and charging capacity."

B. Wiring and Connections:

"Damaged or frayed wires and loose connections can cause electrical failures. Regularly inspect wiring harnesses for damage and ensure all connections are secure and properly grounded."

C. Starter and Alternator:

"Starter motor failures and alternator performance issues can lead to downtime. Regularly inspect and test these components. Ensure proper charging and starting systems."

D. Electronic control modules and sensors.

"Failures in these electronic components can cause a multitude of issues. Diagnostic testing with the proper tools is required."

V. Undercarriage and Tire Maintenance

A. Tire Wear and Damage:

"Proper tire pressure and regular inspections are essential for even tire wear and safe operation. Choose tires appropriate for the operating environment and replace worn or damaged tires promptly."

B. Wheel Bearings and Axles:

"Proper lubrication and regular inspections are crucial for wheel bearing and axle longevity. Check for excessive play and replace damaged bearings or axles."

C. Mast and Carriage:

"Regular lubrication and inspections of the mast and carriage moving parts prevent excessive wear and ensure smooth operation. Inspect chains and rollers for damage and proper tension."

D. Brakes.

"Brake wear can lead to dangerous situations. Regularly check brake wear, and brake fluid levels."

VI. Operator-Related Maintenance Issues

A. Improper Operation:

"Overloading and rough handling can cause significant damage to the forklift. Operators should be trained on proper operating techniques and understand the machine's limitations. Incorrect driving techniques can also lead to premature wear."

B. Lack of Pre-Operation Checks:

"Daily walk-around inspections and fluid level checks are essential for identifying potential problems before they escalate. Operators should be trained to perform thorough pre-operation checks."

C. Insufficient Operator Training:

"Proper operator training is crucial for safe and efficient operation. Operators should be trained on machine operation, safety procedures, and basic maintenance tasks. Understanding the machine's capabilities and limitations is vital."

D. Failure to Report Problems:

"Prompt reporting of any issues to the maintenance team is essential for preventing major breakdowns. Operators should be encouraged to keep daily logs and communicate any concerns."

VII. Preventative Maintenance Strategies

A. Developing a Maintenance Schedule:

"A structured maintenance schedule ensures that all critical components are inspected and serviced at the appropriate intervals. Record-keeping and tracking are essential for monitoring maintenance activities."

B. Utilizing Diagnostic Tools:

"Electronic diagnostic tools help identify engine and hydraulic system problems early. Fluid analysis and testing can provide valuable insights into the condition of fluids."

C. Training and Education:

"Maintenance staff should be trained on the latest maintenance techniques and diagnostic tools. Operator training should cover basic maintenance tasks and safety procedures."

D. Parts and Supplies:

"Proper storage of supplies and the use of OEM or high-quality aftermarket parts are essential for reliable maintenance. Using low quality parts can lead to premature failures."

VIII. Conclusion

"Diesel forklifts are vital assets in many industries, and their reliability hinges on consistent and proactive maintenance. By understanding the common maintenance issues and implementing effective preventative strategies, businesses can minimize downtime, extend equipment lifespan, and enhance workplace safety. Regular inspections, proper lubrication, fluid management, and operator training are essential components of a robust maintenance program. Ultimately, prioritizing preventative maintenance ensures that diesel forklifts operate safely and efficiently, contributing to the overall success of the operation."

Post time:Mar.26.2025