How to Remove a Hydraulic Cylinder from a Forklift

Disclaimer:

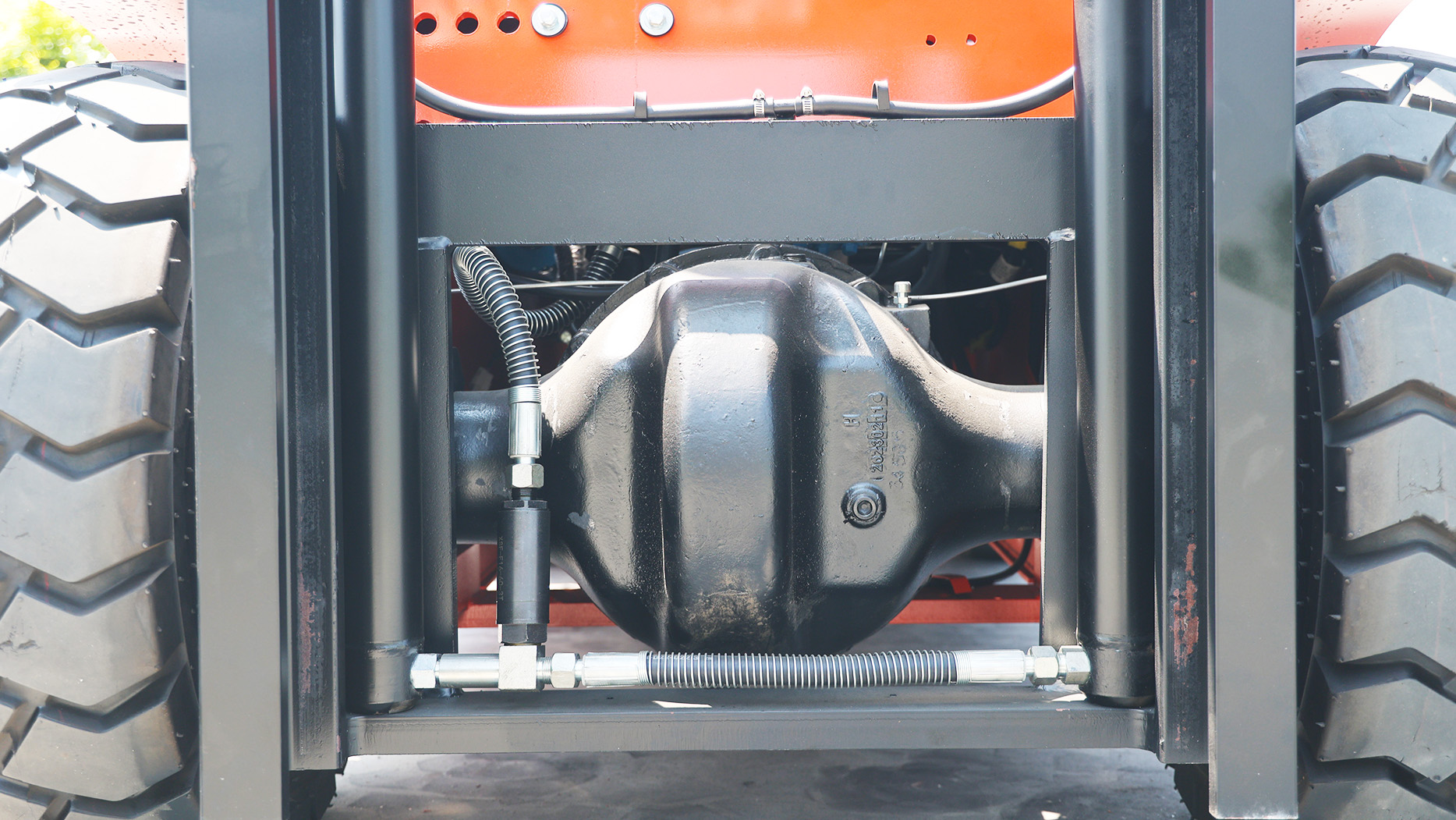

Safety First: Always prioritize safety when working on heavy machinery like forklifts. Wear appropriate protective gear, including safety glasses, gloves, and sturdy footwear.

Consult the Manual: Refer to your specific forklift's manual for detailed instructions and safety precautions.

Professional Assistance: If you're unsure about any step or encounter difficulties, consult a qualified technician or mechanic.

Understanding the Hydraulic Cylinder

A hydraulic cylinder is a mechanical actuator that converts fluid power into mechanical work. In a forklift, it's a crucial component responsible for lifting and lowering the forks.

Tools and Equipment Needed:

Socket wrench set

Wrenches

Hydraulic jack

Jack stands

Safety glasses

Gloves

Penetrating spray

Container for hydraulic fluid

Steps to Remove a Hydraulic Cylinder

1. Preparation and Safety:

Park the Forklift: Ensure the forklift is parked on a level surface and securely chocked to prevent movement.

Lower the Forks: Lower the forks to the ground to relieve pressure on the hydraulic system.

Disconnect the Battery: Disconnect the battery to prevent accidental activation.

Release Hydraulic Pressure:

Locate the pressure relief valve on the hydraulic pump or cylinder.

Use a wrench to slowly open the valve to release the pressure.

Once the pressure is released, you should be able to manually move the cylinder rod.

2. Accessing the Cylinder:

Remove the Hydraulic Lines:

Identify the hydraulic lines connected to the cylinder.

Use a wrench to loosen the fittings and disconnect the lines.

Place a container under the fittings to catch any draining fluid.

Remove the Mounting Bolts:

Locate the bolts securing the cylinder to the forklift frame.

Use a socket wrench to loosen and remove the bolts.

Disconnect Electrical Connectors:

If applicable, disconnect any electrical connectors attached to the cylinder or its sensors.

3. Removing the Cylinder:

Manual Removal:

If the cylinder is relatively lightweight, you may be able to manually lift and remove it.

Use a lifting strap or chain to assist in the removal process.

Using a Hydraulic Jack:

Position the hydraulic jack under the cylinder or a suitable support point.

Slowly lift the cylinder using the jack until it clears the mounting points.

Slide the cylinder out of the forklift frame.

4. Cleaning and Inspection:

Clean the Area: Clean the area around the cylinder mounting points to remove any debris or fluid.

Inspect the Cylinder:

Visually inspect the cylinder for any damage, such as dents, cracks, or excessive wear.

Check the cylinder rod for scratches, pitting, or bending.

Examine the seals and gaskets for signs of wear or damage.

5. Reinstallation (If Necessary):

Prepare the Cylinder:

If you're reinstalling the same cylinder, clean it thoroughly and replace any damaged seals or gaskets.

If installing a new cylinder, ensure it's compatible with your forklift model.

Mount the Cylinder:

Position the cylinder in its original location and align the mounting holes.

Bolt the cylinder to the forklift frame, tightening the bolts to the specified torque.

Connect the Hydraulic Lines:

Connect the hydraulic lines to the cylinder, ensuring a tight fit.

Tighten the fittings to the specified torque.

Connect Electrical Connectors:

If applicable, reconnect any electrical connectors.

Bleed the Hydraulic System:

Follow the manufacturer's instructions to bleed the hydraulic system and remove any air bubbles.

Additional Tips:

Use a Hydraulic Press: For stubborn cylinders, a hydraulic press can be used to exert additional force to remove them.

Protect the Cylinder Rod: Cover the cylinder rod with a protective cap to prevent damage during handling and storage.

Consult a Workshop Manual: Refer to a detailed workshop manual for specific procedures and torque specifications for your forklift model.

Safety First: Always prioritize safety. Wear protective gear and follow proper lifting techniques.

By following these steps and taking necessary precautions, you can successfully remove a hydraulic cylinder from your forklift.

Post time:Dec.11.2024