I. Introduction

Diesel forklifts play a crucial role in various industries, including warehousing, construction, and logistics. Known for their power and durability, these machines are essential for lifting and transporting heavy loads efficiently. However, like all equipment, diesel forklifts have a limited lifespan, and understanding their longevity is vital for businesses aiming to maximize their return on investment.

The lifespan of a diesel forklift depends on several factors, including maintenance practices, operating conditions, and overall build quality. While some forklifts may last for decades with proper care, others may require replacement sooner due to wear and tear. This article explores the factors influencing the longevity of diesel forklifts, typical lifespan expectations, and best practices to extend their service life.

II. Understanding Diesel Forklifts

A. Definition and Primary Functions

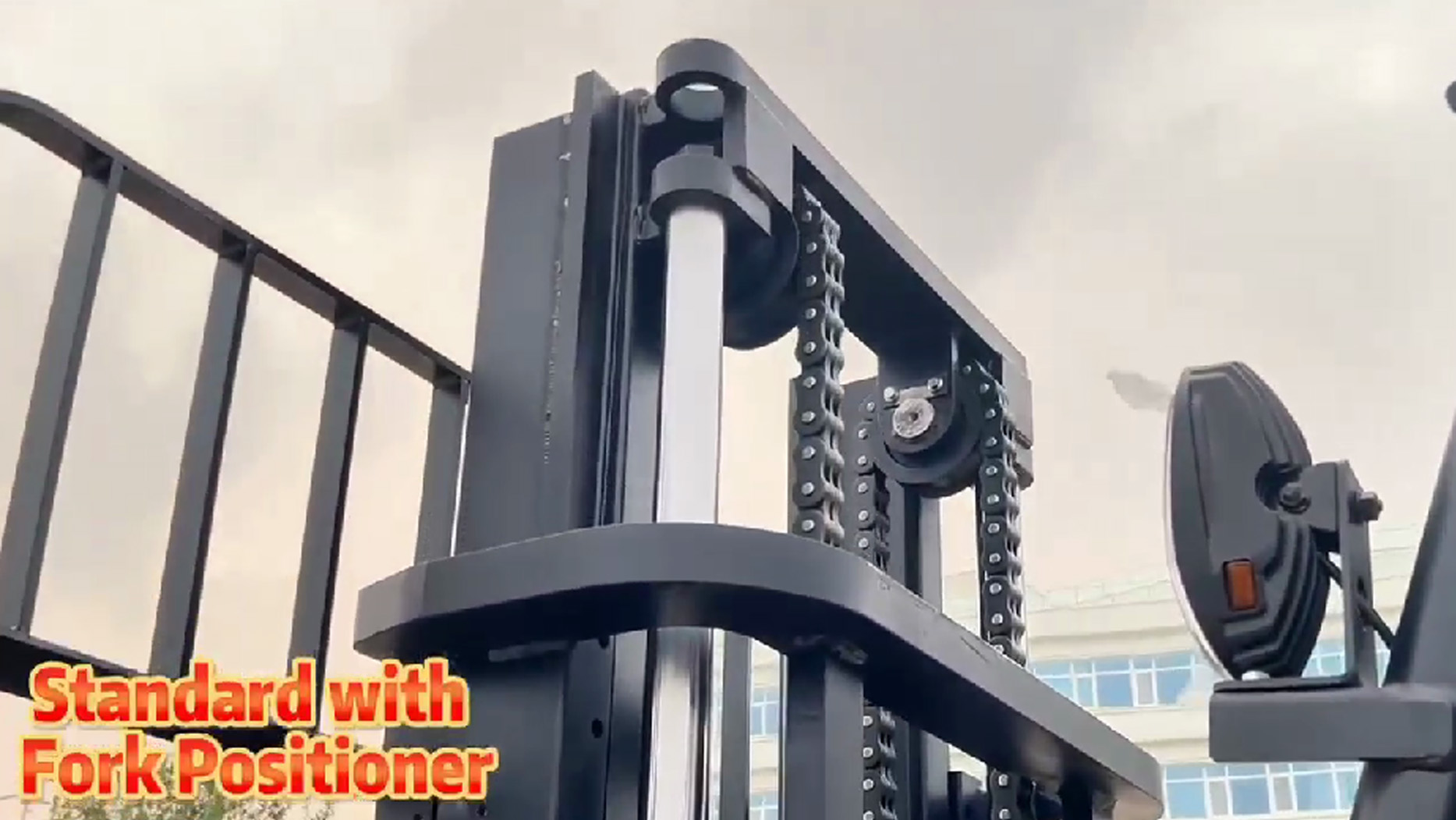

A diesel forklift is a type of industrial vehicle powered by a diesel engine, designed to lift, transport, and stack heavy materials. These forklifts are preferred in outdoor settings due to their powerful engines and ability to operate on rough terrain.

B. Comparison with Electric and LPG Forklifts

Diesel Forklifts: Longer runtime, higher load capacity, and better performance in outdoor environments.

Electric Forklifts: Eco-friendly, lower maintenance, but limited by battery life.

LPG Forklifts: Versatile and lower emissions than diesel, but require frequent refueling.

C. Common Applications in Industries

Warehousing and distribution centers

Construction sites

Shipping yards and ports

Manufacturing plants

III. Factors Affecting the Lifespan of Diesel Forklifts

A. Operating Hours vs. Calendar Years

Typical lifespan ranges between 10,000 to 25,000 hours.

Heavy usage in high-demand industries may reduce lifespan, while lighter use extends it.

B. Maintenance and Servicing

Regular oil changes and filter replacements prevent engine wear.

Hydraulic system checks ensure smooth operation.

Periodic inspections help identify and resolve minor issues before they become major problems.

C. Operating Conditions

Indoor vs. Outdoor: Outdoor forklifts experience more wear due to weather exposure.

Rough Terrain: Uneven surfaces and debris can accelerate wear on tires and suspension systems.

D. Load Handling and Usage Patterns

Overloading reduces engine efficiency and accelerates wear.

Smooth and controlled operation extends lifespan by reducing mechanical strain.

E. Brand and Build Quality

Premium brands offer longer-lasting components and better engineering.

Budget models may require more frequent repairs and replacements.

F. Technological Advancements and Upgrades

Modern diesel forklifts feature improved fuel efficiency and durability.

Upgrading parts, such as transmissions and hydraulics, can prolong usability.

IV. Average Lifespan of Diesel Forklifts

Diesel forklifts typically last between 10,000 to 25,000 hours, depending on maintenance.

Comparison with other types:

Electric forklifts: 8,000-12,000 hours (battery limitations)

LPG forklifts: 15,000-20,000 hours

Industry benchmarks suggest replacing forklifts after 10-15 years in moderate-use environments.

V. Signs That a Diesel Forklift Needs Replacement or Overhaul

A. Decreasing Fuel Efficiency and Rising Maintenance Costs

Frequent refueling and higher diesel consumption signal engine wear.

Increasing repair expenses may make replacement more cost-effective.

B. Frequent Breakdowns and Performance Issues

Repeated mechanical failures reduce operational efficiency.

Difficulty starting or sluggish response indicates engine fatigue.

C. Safety Concerns and Compliance with Regulations

Older forklifts may no longer meet safety standards.

Worn-out brakes, hydraulic failures, and emission issues pose risks.

D. Comparison of Refurbishment vs. Purchasing a New Forklift

Refurbishment: Ideal if major components are still in good condition.

New Purchase: Recommended when repair costs exceed 50% of the forklift’s value.

VI. Case Studies and Real-World Examples

A. Long-Lasting Diesel Forklifts in Warehouse Operations

Example of a warehouse using diesel forklifts for over 20 years with strict maintenance protocols.

B. Heavy-Duty Diesel Forklifts in Construction and Their Durability

Case of a construction company extending forklift lifespan by using reinforced tires and scheduled overhauls.

C. Lessons from Businesses That Maximized Forklift Lifespan

Key takeaways: Proper maintenance, balanced workload distribution, and timely part replacements.

VII. Best Practices to Extend the Life of a Diesel Forklift

A. Implementing a Strict Maintenance Routine

Regular servicing ensures optimal engine performance and reduces unexpected failures.

B. Proper Operator Training and Handling Best Practices

Skilled operators reduce strain on the machine and prevent premature wear.

C. Using High-Quality Fuel and Lubricants

Clean diesel and premium lubricants minimize engine deposits and wear.

D. Strategic Fleet Management to Balance Usage

Rotating forklifts within a fleet prevents overuse of specific machines, extending lifespan.

VIII. Conclusion

Diesel forklifts are essential workhorses in various industries, and their lifespan is influenced by factors such as maintenance, operating conditions, and build quality. While they can last anywhere between 10,000 and 25,000 hours, businesses can extend their service life through regular maintenance, proper handling, and strategic upgrades. Investing in quality equipment and following best practices ensures a longer-lasting and cost-effective fleet, ultimately improving productivity and reducing operational costs.

Post time:Apr.09.2025