Diesel forklifts are powerful and versatile machines commonly used in various industries. While they are primarily associated with outdoor applications, there are specific circumstances and considerations when they can be used indoors. This article will delve into the factors that influence the feasibility of using diesel forklifts indoors, highlighting safety concerns, regulatory requirements, and best practices.

Understanding the Challenges

The primary concern with using diesel forklifts indoors is the emission of harmful exhaust fumes. Diesel engines produce a range of pollutants, including:

Carbon Monoxide (CO): An odorless, colorless gas that can cause headaches, dizziness, and even death in high concentrations.

Nitrogen Oxides (NOx): A group of gases that contribute to air pollution and respiratory problems.

Particulate Matter (PM): Tiny particles that can penetrate deep into the lungs, causing respiratory issues and other health problems.

Sulfur Dioxide (SO2): A gas that can irritate the respiratory system and contribute to acid rain.

These emissions can pose significant health risks to workers if they are not adequately controlled.

Factors Influencing Indoor Use

Several factors determine whether a diesel forklift can be safely used indoors:

Ventilation: Adequate ventilation is crucial to remove exhaust fumes and maintain safe air quality. This can be achieved through:

General ventilation: Utilizing fans, exhaust systems, and open doors and windows to circulate air.

Local exhaust ventilation: Employing systems that capture exhaust fumes directly at the source, such as hoods or extraction arms.

Work Area Size and Configuration: Larger, well-ventilated areas with high ceilings and open floor plans generally offer better conditions for indoor use.

Frequency and Duration of Use: Infrequent or short-term use in well-ventilated areas may pose less risk than continuous operation in confined spaces.

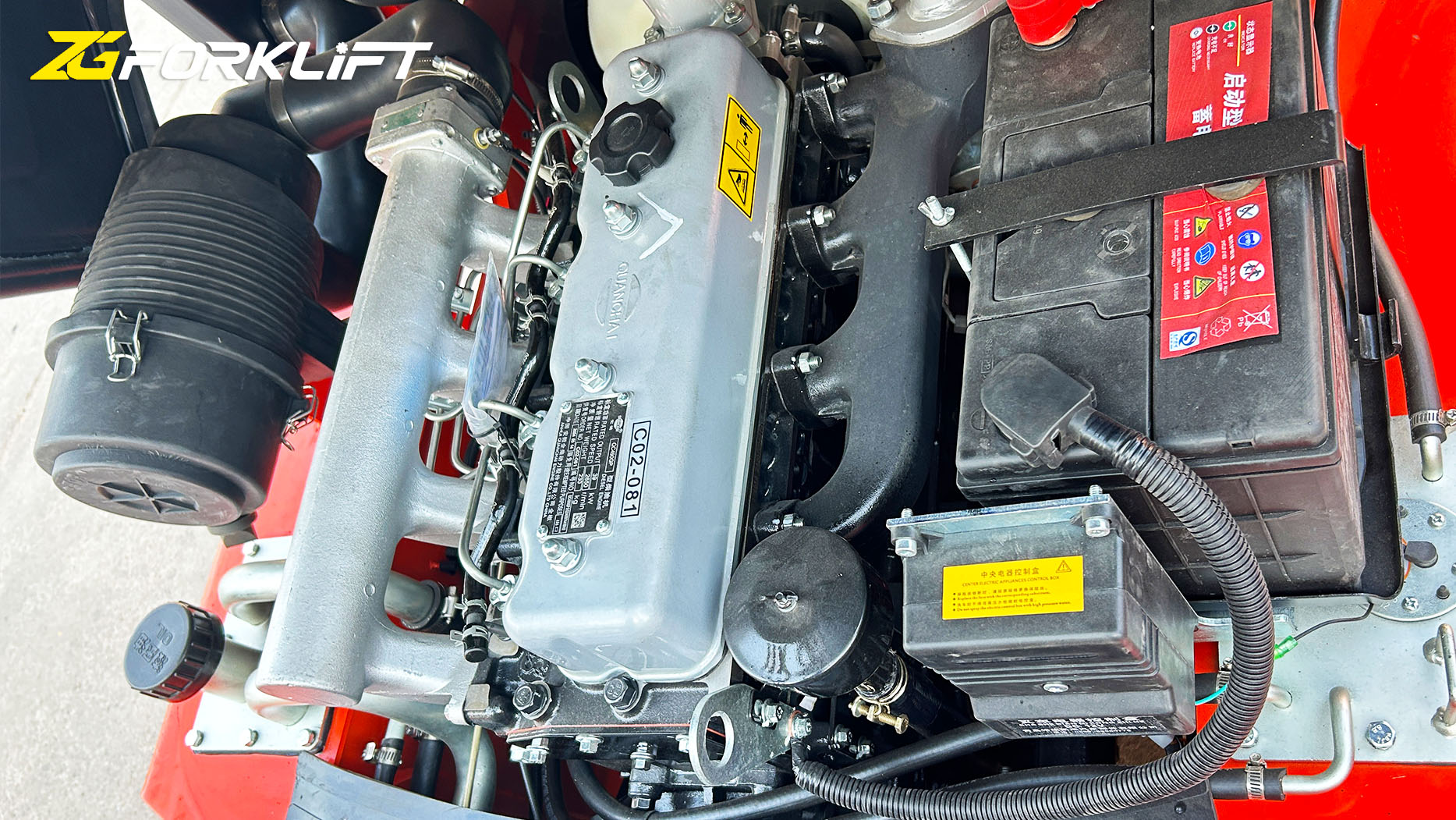

Maintenance and Servicing: Proper maintenance of the diesel engine is essential to minimize emissions and ensure optimal performance.

Operator Training: Operators must be thoroughly trained on safe operating procedures, including recognizing the symptoms of exposure to exhaust fumes and the importance of adequate ventilation.

Regulatory Considerations

Occupational Safety and Health Administration (OSHA) regulations in the United States provide guidance on the safe use of diesel forklifts indoors. Key regulations include:

29 CFR 1910.178: This standard addresses the use of powered industrial trucks, including forklifts. It emphasizes the importance of operator training, equipment inspection, and safe operating practices.

29 CFR 1910.145: This standard addresses occupational exposure to hazardous chemicals, including diesel exhaust. It outlines permissible exposure limits (PELs) for various pollutants and requires employers to implement appropriate controls to protect workers.

Best Practices for Indoor Use

To minimize risks associated with indoor use of diesel forklifts:

Conduct a risk assessment: Evaluate the specific hazards associated with indoor use in your particular workplace.

Implement engineering controls: Prioritize engineering controls, such as local exhaust ventilation, to effectively remove exhaust fumes.

Use administrative controls: Implement work practices to minimize exposure, such as limiting operating times and scheduling work during periods of good ventilation.

Provide personal protective equipment (PPE): When engineering and administrative controls are insufficient, provide appropriate PPE, such as respirators, to protect workers from exposure.

Regularly monitor air quality: Conduct air quality monitoring to ensure that exposure levels remain below permissible limits.

Maintain equipment properly: Ensure that diesel engines are properly maintained to minimize emissions.

Provide comprehensive operator training: Train operators on safe operating procedures, recognizing the symptoms of exposure, and the importance of following safety guidelines.

Alternatives to Diesel Forklifts

In many cases, alternative power sources may be more suitable for indoor applications, such as:

Electric forklifts: These are zero-emission vehicles that are ideal for indoor use, especially in confined spaces.

Liquefied Petroleum Gas (LPG) forklifts: LPG forklifts produce fewer emissions than diesel forklifts and are a viable option for some indoor applications.

CNG (Compressed Natural Gas) forklifts: CNG forklifts offer a cleaner alternative to diesel and can be used indoors with proper ventilation.

Conclusion

While diesel forklifts can be used indoors under certain conditions, it is crucial to prioritize worker safety and comply with all applicable regulations. By implementing appropriate controls, such as adequate ventilation and regular monitoring, and by providing comprehensive operator training, it is possible to minimize the risks associated with indoor use of diesel forklifts. However, in many cases, alternative power sources may be more suitable for indoor applications due to their reduced emissions and improved safety profiles.

Post time:Jan.27.2025